Used Ruhle SR1 Turbo Dicer HighTech Cutting machine SR 1 Turbo

The multifunctional top performer

Exellent cuts, varied fields of application, high hourly capacity and hygiene properties which makes cleaning in less then five minutes possible. These are capacity-parameters, which could only be obtained by new machine-concept, that helps to make working and operating easier.

Technical Details

| Length of machine: | 900 mm |

| Width of machine: | 600 mm |

| Height of machine: | 980 mm |

| Weight of machine: | 280 kg |

| Connected load: | 1,5 kW / 16 A |

| Width of shaft: | 100 mm |

| Height of shaft: | 100 mm |

| Length of shaft: | 350 mm |

| Section length: | 1 - 32 mm |

| Sections: | 160 pro/min |

| Cutting temperature: | -5°C - +80°C |

| Cutting output: | 1500 kg max. |

| Standard grid-sizes: | 5, 10, 20, 50 / 6, 12, 24, 50 / 7, 15, 30, 50 |

The compacting system

The angled shaft with the linear pre-compacting and the pre-compacting from the sides together make up the Rühle-compacting system. This shaft construction has the feature that strings of chops, sausages or loose source material remain stable in the shaft even if the pre-compacting systems are not required. The corner of the angled shaft pointing down ensures that hold is provided on two sides if, for example, thinner sausages have to be portioned into thin slices.

The change-over-comfort

It only takes 10 seconds to change over the multiplex grids.

This makes fully automatic cutting of even small amounts profitable.

You save time for preparation, cleaning and, because everything works so simple, you avoid operating errors.

The sectioner

The relief-ground Rühle blade causes practically no friction because it only grinds the blade over the source material as much as it is necessary. But then again the blade is so strong that it always takes bone-hard insertions and hard knocks in its stride. Thus even difficult source materials end up with a superb cut appearance.

Side compacting

Apart from the ordinary pre-compacting, which is capable of compacting in the processing shaft, an inclined shaft and a side-compacting supplement the system so that you have the perfect cutting preparation. The product has a secure grip in the inclined shaft and is compacted gently and evenly from all sides.

This allows for precise portioning.

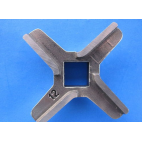

The multiplex grid

It only takes one grid frame and two grid halves to produce 10 different cut-sizes. That’s why you can have the complete equipment and the greatest flexibility at a low cost.

Wether portioning, small cubes or large stripes, you have the complete variety, even up to cutlets, roulades or steaks.

The serrated knives

Would the blade of the grid knife be straightened, it would be twice as long. This is the reason, why already half the movement of the blade results in very beautiful cuts. This results in less heat and movement inside the product and the result is a better cut This applies especially for stringy products.

Equipment

- Serrated knives

- Angled shaft

- Toolbox

- Stabilisers for source material

- Single foot undercarriage

- Pressure sensitive pre-compacting

- Multiplex-grid on roller bearings

- Infinite adjustment of forward feed 1-32

- Mechanical pressure system

- Pre-compacting from the sides

-238x94.jpg)